#Paintpro fanuc code#

The workflow is simplified where we can import a cad model of your part, create a tool path, generate robot code that can then be used on your robot as a precise path to follow. These are typically applications where we use a robot, machine or grind parts. RoboDK- There are certain applications when we prefer to use another simulation/programming environment such as RoboDK. The robot paths created in PalletPro can be downloaded to a real robot controller simplifying the teaching process. If you want to try it, you need to talk to a Fanuc representative, or. I don’t know why Fanuc is restricting access to their software. Unfortunately, you cannot register by yourself.

#Paintpro fanuc trial#

Hundreds of unit load pallet configurations can be created and visualized in 3-D using the built-in library of standard patterns. Roboguide is available in a free trial version and can be downloaded from the Fanuc website (for registered users). Allows users to create a work cell layout, in-feed, out-feed, pallet stations, and pallet dispensers. PalletPro- Used to completely build, debug and test palletizing applications. This makes otherwise time consuming programming very simple especially when total and even paint coverage is extremely important.

#Paintpro fanuc software#

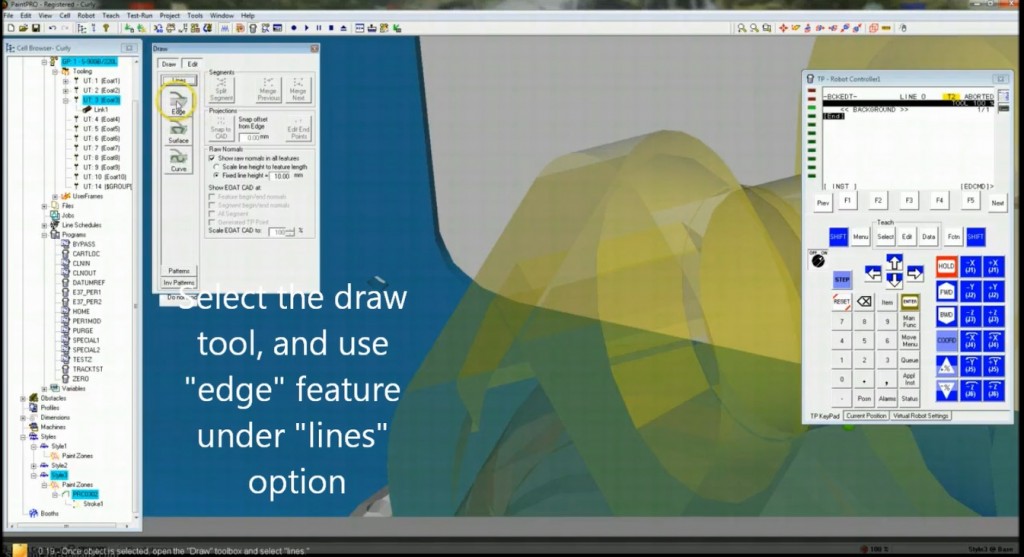

FANUC PaintPRO software is a graphical of offline programming solution that simplifies. The operator automatically generates robot programs by graphically selecting the area of the part to be painted and chooses between several painting methods. ZDT Protect your investment with FANUCs proven IoT solution. PaintPro- Graphical offline programming solution that simplifies the robotic path, teach, and paint process development. Programs and settings from the virtual environment can be transferred to the real robot to decrease installation time. Has the capability to control and modify torch angles and process parameters. WeldPro- Simulates robotic arc welding process. Features include CAD to Path programming, conveyor line tracking, machine modeling and programming. HandlingPro- Used for material handling applications including loading and unloading, packaging, assembly and material removal.

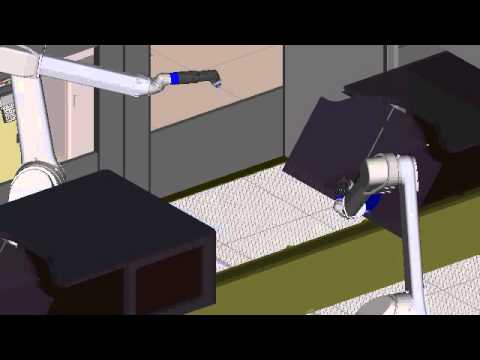

Within the virtual environment accurate time estimates can be created to ensure that production numbers can be met. Proposals/Time estimates- We use Roboguide to develop accurate proposals. This eliminates weeks of lost time and money due to a simple overlooked detail. Offline Programming- Roboguide also allows users to program new changes into a robotic cell, and make sure everything will work before shutting down a production line. We can provide you with a “virtual view” of what will be built so you can see how everything will work together. Roboguide- Fanuc’s simulation software, Roboguide, provides a virtual view of what the automated work cell would look like. We do part of our quoting process within Roboguide to get accurate estimates on processing time and cell floor layout. FANUC robotics has an incredible simulation software package called Roboguide that allows you to see exactly what you get before you put any money down. This helps you plan your floor layout and know exactly what you are getting before we build it.

Your robot cell can be represented digitally and simulated to show how a program will work before running production, or even building the work cell.

0 kommentar(er)

0 kommentar(er)